Add Your Heading Text Here

- Tips

- FAQ

- Troubleshoot

- Contact Us

- Support

Tips

Dear Livoltek users or installers, here you can find some general tips before you start using or installing Livoltek products.

On-grid Inverter

1)The installation carrier is sturdy and can bear the weight of the inverter for a long time.

2)It is recommended that the installation ambient temperature be lower than 50°C and the ventilation should be good.

3)In order to ensure the best operation, it is necessary to avoid direct sunlight, rain and snow.

4)During operation, the case temperature will be relatively high, please do not install the inverter in a place where it is easy to touch.

5)The space around the inverter must meet the installation, maintenance and heat dissipation requirements.

Vertical installation/ Do not allow lying down/ Leaning back and inversion

1)Do a good job of line marking to reduce the probability of errors

2)Before connecting to the inverter, use a multimeter to measure the input voltage of the component on the positive and negative sides to ensure that the polarity is correct and does not exceed the maximum input voltage

3)Use special crimping tools for photovoltaic terminals

4)If conditions permit, you can use an infrared thermal imager or a spot temperature gun to confirm the connection point temperature after grid-connected power generation.

1)Tighten the cable gland

2)Idle interfaces are sealed

3)The cable entry cover is closed

4)Conduit sealing treatment

5)Confirm and lock the waterproof cap

1)Weather Reason

2) Ambient Temperature

3)Component Orientation

4)Distance Between Components

5)Component Inclination

6)Dust Shielding

7)Component mismatch

8) Component Virtual Label

9)Grid Instability

10) Inverter Reports Fault

1)Poor Wi-Fi signal

2)GPRS signal is not good

3)Home broadband arrears

4)Problems with router settings

5)Router failure

6)The router is overloaded

7)The module interface is loose

8)Mixed wiring of communication lines and power lines

9)Communication module failure

10)Inverter failure

Energy Storage System

There are 4 types of EPS modes, they are:

0 – Disable

1 – EPS without bypass:only in the case of power failure, EPS port will have voltage output (basically no standby power consumption)

2 – EPS with bypass:When there is power grid, EPS port will also have voltage output, and when power failure, EPS port voltage will need about 2s for output switch (low power standby power consumption).

3 – UPS with bypass:EPS port also has voltage output when there is power grid, and UPS mode output when power failure, EPS port voltage needs <20ms time for switching (high power standby power consumption)

EV charger

1)When the charger is connected to the power line, the front end must be forcibly connected to a Type A/30mA RCBO.

2)The default Bluetooth name of the charger is AC – {SN last 8 digits}, and the default password is 111111.

3)Installation environment Requirements

-The installation position of charger shall not be close to dangerous positions such as water pipe, gas pipe and steam pipe.

-The charger shall not be installed in places with severe vibration or high temperature.

-The installation position of charger should not be set in low-lying places where it is easy to accumulate water or drip.

-It is recommended that the charger be installed in an environment with sunshade or umbrella.

-A certain space shall be reserved for the installation of charger to facilitate the inspection and maintenance of technicians.

*Including but not limited to the above.

4)The length of the vehicle connector is 5m by default, which can meet the daily charging use. Special length requirements can be customized.

FAQ

Dear Livoltek users or installers, here you will find our most frequently asked questions and their answers, which we have grouped together in order to help you solve your problems quickly.

On-grid Inverter

Different models have different requirements, the specific reference is as below:

| (Top) | (bottom) | (Left) | (Right) | |

| 1-36kW | >500mm | >600mm | >200mm | >200mm |

| 50-60kW | >600mm | >600mm | >400mm | >400mm |

| (Front) | |

| 1Phase | >500mm |

| 3Phase | >1000mm |

Wall Mount and Bracket Mount

1)It is recommended to connect the protective grounding and the PE terminal of the AC wiring at the same time.

2)The diameter of the protective grounding cable should be the same as that of the AC output PE cable.

3)In order to improve the anti-corrosion performance, it is recommended to apply silicone or paint on the outside of the ground terminal for protection.

4)Near-end grounding is recommended. For a system with multiple inverters connected in parallel, ensure that each grounding wire is connected to the same potential.

1) When connecting photovoltaic modules to the inverter, the Amphenol H4 photovoltaic special connector provided with the inverter should be used. Compatible models may not guarantee long-term effective contact of metal terminals.

2) When crimping the positive metal terminal, do not also crimp the limit stop bar, otherwise the metal terminal will not be stuck, resulting in “heading”

3)Strictly prevent the reverse polarity of the DC input. It is forbidden to connect the single group in series in the same MPPT. Make sure that the terminal is correct before inserting the terminal into the inverter (it is recommended to use a multimeter to measure)

1)Pay attention to the correct connection of the neutral wire polarity

2)It is forbidden to connect the load to the output terminal of the inverter without passing through the circuit breaker;

3)Each inverter needs to be equipped with an independent circuit breaker to ensure safe disconnection from the grid

4)When using multiple single-strand cables for AC output, use fireproof mud to seal the gap between the sealing ring and the cable after wiring is completed.

5)When a large number of single-phase output inverters are connected to the same low-voltage transformer in the three-phase power grid, attention should be paid to the reasonable distribution of the inverters among the three phases, and the load balance of the three phases should be maintained as much as possible to avoid the failure of a certain phase due to insufficient consumption. The phase voltage rises and damages the electrical equipment;

| Indicator light | Mode | Instructions |

| Grid Indicator light | Twinkling | At least one of the PV strings has a voltage greater than 90V |

| On (Twinkling Power Display ) | When the machine is connected to the grid for power generation, every 30 seconds is a cycle. The first few seconds of flashing indicate the power level, and it is always on after flashing. Less than 20% rated power, every 30 seconds, flash once 20%-40% rated power, 30 seconds interval, flashing 2 times 40%-60% rated power, interval 30 seconds, flashing 3 times 60%-80% rated power, 30 seconds interval, flashing 4 times 80%-100% rated power, 30 seconds interval, flashing 5 times | |

| Communication indicator | Off | There is no communication connection or the communication is abnormal |

| Twinkling | A certain communication mode of Bluetooth, WIFI, GPRS, RS485 communicates normally | |

| Warning Light | Off | The machine has no warnings and no faults |

| Twinkling | The machine has a warning |

1)Make sure to use terminal blocks for lock wire

2)Make sure the terminals are locked

3)Do not lock the screw to the cable insulation

Energy Storage System

- Start for On-Grid:Grid→EPS→PV→Battery

- Start for Off-Grid:Battery→PV→EPS→Grid

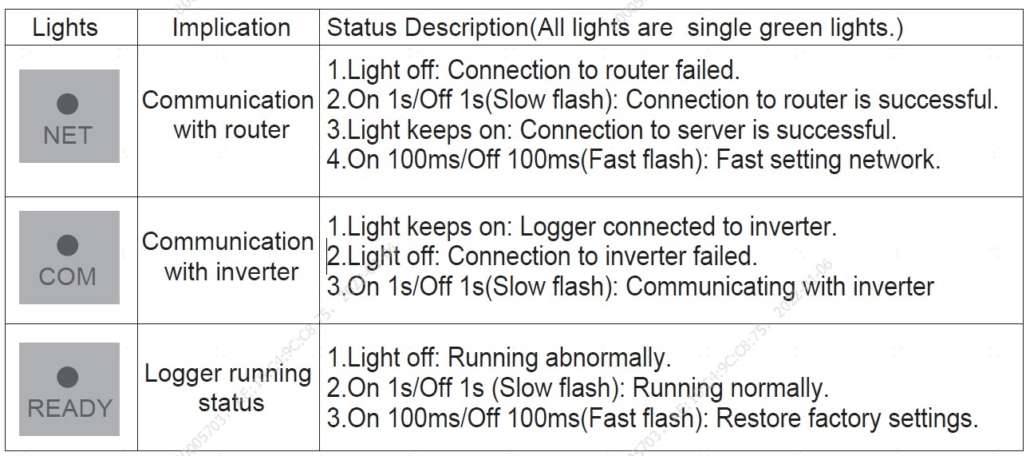

When the inverter is turned on, the NET light is off because the router is not connected. The COM light is on because the collector is connected to the inverter. The READY light flashes slowly (1s on and 1s off), which means the collector usually runs.

Search for the keyword Propower from Google Play Store or Apple AppStore, download and install the latest version software for free.

- Connect to the Logger’s network (Wi-Fi name is AP_*******)

- Wi-Fi name and Password in Logger`s positive

- A cell phone connects to the Logger’s Wi-Fi

- Search the inverter list, and connect to the target inverter

- If it is successfully connected, the home page will show the general status of the inverter.

- Go to setting page, choose Inverter Commands.

- Then click on the Time&Date Sync icon to Synchronize system time for inverter

- Let end customers use mobile phones to download and installation Solarman App

- Click Register to enter end client user name, email address, password, and click Register to Register end client user account

- registering the account,Click + to build Plant

- Automatically pops up the scan interface and scans Wi-Fi Logger SN for Build Plant

- Please fill in Plant Address、Capacity、Currency、name and your Contact information.Click Complete to build Plant.

EV charger

It is not required. Because we have a DC isolator already added on the battery side.

It is 125A, 1.25 times rated power of battery.

6000 Cycles. (Test conditions: 0.2C Charging/Discharging, @25°C, 80% DoD, 60% EOL)

Battery

XXXXXXXXE11 is applicable to Type 2 connectors, and XXXXXXXXE12 is

applicable to Type 1 connectors.

Currently, this EV Charger only communicates with Livoltek Hyper 5000 inverter.

When users connect to Bluetooth for the first time, please enter password 111111

and connect to the last 8 digits of the EV Charger serial number. Then next time,

for the same phone, users do not need to enter the password.

Please use 2.4 GHz Wi-Fi to connect EV Charger online.

The network name should be the English alphabet and numbers.

Yes, please connect the grounding line.

Troubleshooting

Dear Livoltek installers, here you will find a list of problems that you may encounter during the installation or use of our products and their quick fixes, which we have grouped together to help you solve them quickly.

On-grid Inverter

| Product Name | Alarm Definition | Processing Strategies |

| A00-Grid AC over voltage | The grid voltage exceeds the allowable range | 1. If the alarm occurs occasionally, it means the grid abnormal, the inverter can automatically recover to normal operating status after the grid return normal. 2. If the alarm occurs repeatedly and it can automatically recover, need to contact local electric power department to get permission to modify the inverter grid protection parameters with APP. 3. If the alarm occurs repeatedly for a long time, please confirm 1) If the output breaker is closed? 2)If the output terminal is ok? 3)If grid is power off? 4)If the output cable follow the User Manual guidance? |

| A01-Grid AC under voltage | ||

| A02-Grid AC absent | The grid voltage is 0 volt | |

| A03-Grid AC over frequency | The grid frequency exceeds the allowable range | |

| A04-Grid AC under frequency | ||

| B00-PV DC over voltage | PV module input voltage is higher than the allowable range | Please measure the PV input voltage with multimeter, and compare it with the “Max input voltage” written the inverter lable. If PV input voltage is larger than “Max input voltage”, then reduce the PV module quantity. |

| B01-PV insulation abnormal | The insulation resistance against the ground is lower than the allowable range | 1. If the alarm occurs occasionally, it may be caused by external circuit, the inverter can automatically recover to normal operating status after the fault is cleared. 2. If the alarm occurs repeatedly or lasts a long time, please follow below steps: 1) Check if the output cable is stable. 2) Plug the PV strings one by one to find the abnormal PV strings. Please check if the insulation resistance against the ground of PV strings is too low, or the cable is broken, or cable connection incorrectly. |

| B02-Leakage current abnormal | The residual current is high. | 1. If the alarm occurs occasionally, it may be caused by external circuit, the inverter can automatically recover to normal operating status after the fault is cleared. 2. If the alarm occurs repeatedly or lasts a long time, please follow below steps: 1) Check if the output cable is stable. 2) Plug the PV strings one by one to find the abnormal PV strings. Please check if the insulation resistance against the ground of PV strings is too low, or the cable is broken, or cable connection incorrectly. |

| B03-PV string abnormal | PV strings have been shielded for a long time or PV strings is abnormal | 1. Check whether the PV string is shielded. 2. If the PV string is clean and not shielded, check if the PV modules are aging or deteriorated, or if cable/terminal is abnormal. |

| B04-PV DC under voltage | PV modules input voltage is under default protection value. | 1. If alarm occur during sunlight weak(At morning or dawn, raining or ), it’s normal and no action is needed. 2. If not, please check if there is PV module connection short circuit. |

| A06-Grid voltage unbalanced | The grid voltage unbalanced exceeds the allowable range | 1. If the alarm occurs occasionally, it means the grid abnormal, the inverter can automatically recover to normal operating status after the grid return normal. 2. If the alarm occurs repeatedly and it can automatically recover, need to contact local electric power department to get permission to modify the inverter grid protection parameters with APP. 3. If the alarm occurs repeatedly for a long time, please confirm 1) If the output breaker is closed? 2)If the output terminal is ok? 3)If grid is power off? 4)If the output cable follow the User Manual guidance? |

| C02-Output DC over current | Grid DC component current is higher than than the allowable range | 1. If the alarm occurs occasionally, it’s caused by grid voltage abnormal temporarily, the inverter can automatically recover to normal operating status, no action is needed. 2. If the alarm occurs repeatedly or lasts a long time, please contact customer service center. |

| C03-Inverter relay abnormal | Internal relay abnormal | 1. If the alarm occurs occasionally, it’s caused by grid voltage abnormal temporarily, the inverter can automatically recover to normal operating status, no action is needed. 2. If the alarm occurs repeatedly or lasts a long time, please check if output neutral line and fire line reverse connection. If not, please contact customer service center. |

| C05-Inverter over temperature | Internal temperature is higher than than the allowable range | 1. If the alarm occurs occasionally, the inverter can automatically recover to normal operating status, no action is needed. 2. If the alarm occurs repeatedly or lasts a long time, please check if the installation site is direct sunlight, ventilation is good, the ambient temperature is too high. If not, please contact cusomer service center. |

| C06-Leakage current HCT abnormal | Residual current device test is failure | 1. If the alarm occurs occasionally, it may be caused by external circuit abnormal, the inverter can automatically recover to normal operating status after fault is cleared. 2. If the alarm occurs repeatedly or lasts a long time, please check if the insulation resistance against the ground of PV strings is too low, or the cable is broken, or cable connection incorrectly. |

| B07-PV string reverse | The polar of PV strings is reversed. | Check whether the cables of PV strings are correctly connected. If they are connected reversely, reconnect the cables. |

| C08-Fan lock | Fan abnormal | 1. If the alarm occurs occasionally, please restart inverter. 2. If the alarm occurs repeatedly or lasts a long time, please check if fan is blocked. If not, please contact customer service center. |

Energy Storage System

1.Common Customer Complaints-Installation Stage

Earth fault: F2: 00000001

| S/N | Probable Cause | Recommended Measure |

| 1 | The inverter ground wire is not connected properly | 1.Check the inverter ground wire connection. 2.Check the voltage between N&E, it should be under 30V; If it is over 30V,check the connection of the home ground wire |

| 2 | The voltage between N&E is too high | |

| 3 | Inverter damaged | Replace inverter |

Meter Communication Failure: F3: 00000400

| S/N | Probable Cause | Recommended Measure |

| 1 | The meter cable is not connected or the connected communication port is wrong | Check the meter connection wire harness and ports |

| 2 | Communication matching resistance is incorrect | Add matching resistance to the communication terminal of the meter |

| 3 | Inverter meter type setting is incorrect | Check the meter type parameter settings |

| 4 | The line sequence of the RJ45 head is incorrect or the line sequence of the communication port of the meter is incorrect. | Check the color and line sequence of the meter communication line according to the user manual |

| 5 | Bad meter communication harness | Replace the communication harness, UTP is recommended |

| 6 | Meter damaged | Replace meter |

| 7 | The meter communication port of the inverter is damaged | Replace meter |

BMS communication failure: F3: 00004000

| S/N | Probable Cause | Recommended Measure |

| 1 | The BMS communication cable is not connected or the interface is incorrectly inserted | Check BMS wiring harness and connection ports |

| 2 | Inverter battery type parameter is incorrect | Check inverter parameters |

| 3 | Bad BMS communication harness | Replace the BMS communication harness, UTP is recommended |

| 4 | Bad battery BMS communication port | Replace battery |

| 5 | Bad inverter BMS communication port | Replace inverter |

2.Common Customer Complaints—Utilization Stage

When switching between on-grid and off-grid, the switching time of EPS ports is too long, which cause power failure of some loads.

| S/N | Probable Cause | Recommended Measure |

| 1 | Inverter EPS mode setting is incorrect | Check the EPS mode setting. Setting 1 switching time is 2-3S, but the standby power consumption is the lowest, setting 2 switching time is about 1S, with bypass function, standby power consumption is low, setting 3 switching time 20ms, UPS function, standby power consumption average 50- 60W |

| 2 | When the grid is powered off, it is just in the inverter grid connection stage | UPS switching is not supported at this stage |

| 3 | There are too many rectified loads and inductive loads in the home, which will cause prolonged on-grid switching | When there are too many rectifying loads and inductive loads, the switching time can last for 30ms, and some loads will lose power, especially some lamps. |

| 4 | The EPS port is connected to an electrical appliance with an impulse starting current load, and exceeds the inverter load capacity | EPS ports cannot be connected to loads with high impulse current, such as water pumps |

PV does not generate power or generates little power

| S/N | Probable Cause | Recommended Measure |

| 1 | Weather reason | Check historical data to see if it is weather reason |

| 2 | Set 0 feed in, to meet no feed in logic | Check settings |

| 3 | The system insulation resistance value is detected, but the inverter is in the standby state of connection | Check whether the inverter connection is stopped at 1, and check whether the system insulation resistance value is less than 30K |

| 4 | Inverter MPPT working mode parameter setting is incorrect | Check the MPPT working mode, it should set to 0 |

| 5 | The system working state is wrong or the bus voltage state is wrong | Confirm whether the system is in PV working state 5 or 6, and check whether the bus voltage is normal, 400V, 450V, 440V. If the status is wrong, try to restart the inverter |

Battery does not discharge

| S/N | Probable Cause | Recommended Measure |

| 1 | The current battery SOC has reached or is lower than the preset discharge cut-off SOC value | Check the parameters |

| 2 | The battery is not allowed to discharge, for example, the BMS allows the discharge current to be 0 | Check BMS information, confirm battery working status |

| 3 | Inverter is set to backup mode or set to forced charging state | Check the inverter working mode setting and ES control status, 1 is self-use, 3 is forced charging, 5 is forced discharging |

| 4 | The battery voltage is under 50V | Check if the battery voltage is under 50V |

| 5 | The system working state is wrong or the bus voltage state is wrong | Confirm whether the system is in the battery working state 3 or 6, and check whether the bus voltage is normal, 400V, 450V, 440V. If the status is wrong, check whether the battery port of the inverter has voltage or try to restart the inverter |

| 6 | Inverter battery discharge circuit damaged | Replace inverter |

The battery does not charge

| S/N | Probable Cause | Recommended Measure |

| 1 | The inverter set forced discharge | Confirm the status of ES control, 1 is for self-use, 3 is forced charging, 5 is forced discharging |

| 2 | The battery is not allowed to charge, the battery BMS allows the charging current to be 0 | Check BMS information to confirm battery working status |

| 3 | When charging stopped, the battery voltage is over 53.5V and does not meet the conditions for recharging | Check the battery history charging status, check the battery voltage curve |

| 4 | In spontaneous self-use mode, the load is larger than the PV power | Check the working status of the system to confirm whether it conforms to the working logic |

| 5 | The system working state is wrong or the bus voltage state is wrong | Confirm whether the system is in the battery working state 3 or 6, and check whether the bus voltage is normal, 400V, 450V, 440V. If the status is wrong, check whether the battery port of the inverter has voltage or try to restart the inverter |

| 6 | The inverter charging circuit is damaged | Replace Inverter |

Bus overvoltage fault :F1: 80000400

| S/N | Probable Cause | Recommended Measure |

| 1 | Panel open circuit voltage is too high | Check and confirm the configuration of the panel, note the effect of temperature on the open circuit voltage of the panel |

| 2 | In off-grid mode, some loads with short-term impulse current will trigger | Some loads are not recommended to be connected to the EPS port, such as water pumps. If they must be connected, a soft starter needs to be added. |

| 3 | In the case of weak grid, the inverter control loop oscillates | Need to adjust software PI parameters |

| 4 | When in multiple machines parallel mode, the inverter is disturbed | Try to add an inductor at the grid end |

| 5 | Inverter damaged | Replace inverter |

Overcurrent fault F1: 18004800

| S/N | Probable Cause | Recommended Measure |

| 1 | Some special loads will cause the inverter to report overcurrent, such as water pumps, washing machines, etc. | Try to add inductance at the grid end, soft start and other measures |

| 2 | When in multiple machines parallel mode, the inverter is disturbed and causes vibration | Try to add an inductor at the grid end |

| 3 | Inverter hardware damage | Replace inverter |

Grid-connected relay failure: F2: 00000010

| S/N | Probable Cause | Recommended Measure |

| 1 | The inverter is disturbed by the grid | Try to restart the inverter, some old hardware version inverters can try to add an inductor on the grid side to solve the problem |

| 2 | There is a problem with the relay control circuit | |

| 3 | Grid end cement resistance failure | The cement resistance can be skipped by setting the parameter. Reserved 1 is set to 1 to not use the cement resistance, and set to 0 to use the cement resistance. |

Contact Form

Dear users, if you encounter any problems during the use or installation of Livoltek products, you are welcome to fill in the contact form below.

Our after-sales engineers will help you to solve the problem the first time.

Support

Pakistan’s Best Support Service For Solar Energy

We Offer Dedicated Support For Solar Energy In Pakistan

We take pride in our efficiency in performing dedicated service support for solar energy in Pakistan. You can count on our knowledge, skills, and experience, and rest assured that we will guide you perfectly on every step of the process or issue. Whether you want to know things about solar batteries or solar water pumps, or anything in between, you can get in touch with us to get the answer you were looking for. We’ve been in the industry for numerous years and can reassure you that our service is renowned for being quick and reliable. And the experts at LIVOLTEK will go the extra mile to maintain that reputation. So you can rely on us to ensure we’ve got you covered with the best service support for solar energy products in Pakistan! If this sounds like the service support you were looking for, feel free to reach out to us today! We will get back to you in a minimal time.